Who Makes Porsche Engines? Unveiling The Power Behind The Performance

Share

Porsche is synonymous with high-performance vehicles and exceptional engineering. As a brand, it has built a reputation not just for aesthetics but also for pioneering technology that elevates driving experiences. One of the most critical aspects of any vehicle’s performance is its engine, and when it comes to Porsche, there’s an intriguing story about who makes these impressive engines.

In this article, we’ll delve into the various factors that contribute to Porsche's engine manufacturing, highlighting the dedicated teams and technologies behind the brand’s iconic engines.

The In-House Engineering Marvel

Porsche manufactures its engines at its headquarters in Stuttgart, Germany. The commitment to excellence starts right at the heart of the production, where precision engineering and quality control converge. This is crucial, as every engine must not only meet but exceed the high expectations of Porsche enthusiasts and customers around the globe.

The engineering teams at Porsche consist of highly skilled professionals with expertise in various fields such as mechanical engineering, materials science, and thermodynamics. They collaborate seamlessly across departments to develop and refine engines that deliver power, efficiency, and low emissions.

A Legacy of Innovation

Porsche has a storied history that can be traced back to the early 20th century. The founding of the company by Ferdinand Porsche in 1931 laid the groundwork for a legacy of innovation. Throughout the decades, the company has continuously evolved its engine technology, from the air-cooled flat-six engines of the iconic 911 models to the advanced turbocharged engines found in the latest line-up.

With the growing concern for environmental sustainability, Porsche has also made significant strides in developing hybrid and electric engines. The introduction of the Porsche Taycan showcases the brand’s capability to adapt to an electrified future while maintaining the performance characteristics that enthusiasts expect.

The Importance of Research and Development (R&D)

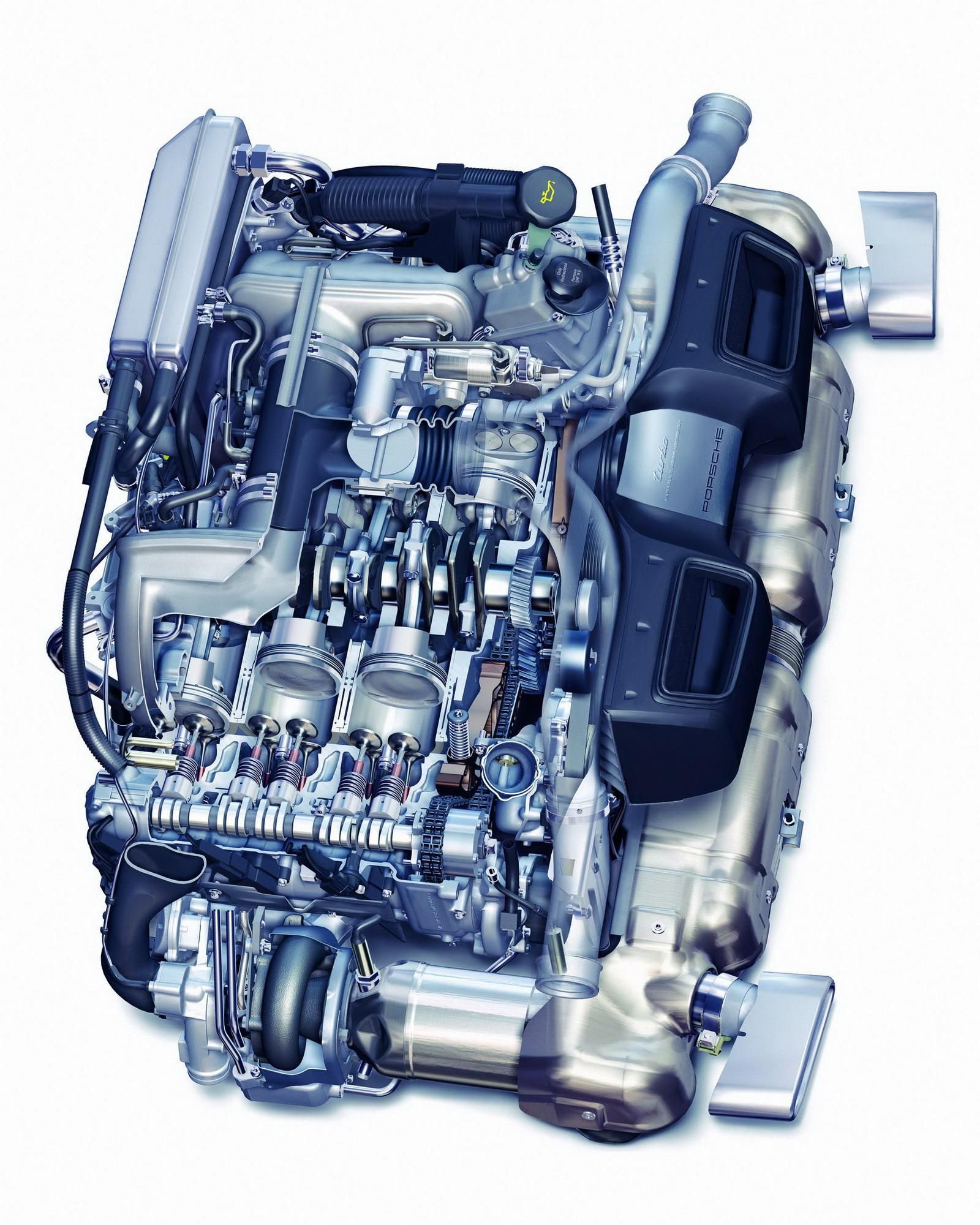

A significant portion of Porsche’s success can be attributed to its unwavering investment in research and development. The company allocates a substantial budget to R&D to explore new materials, technologies, and methodologies that enhance engine performance. Innovative technologies like direct fuel injection, variable valve timing, and advanced turbocharging have made their way into Porsche engines, providing a perfect blend of power and efficiency.

Porsche’s commitment to R&D is not just about maintaining its performance edge; it also aims to comply with increasingly stringent global emissions regulations. The development of engines like the 3.0L Porsche 911 turbo engine has exemplified how the brand can achieve impressive performance while meeting environmental standards.

Collaborations and Partnerships

While Porsche is recognized for its in-house engineering capabilities, it is worth noting that the brand also collaborates with external partners for specific components and technologies. For instance, high-performance components like turbochargers, fuel injectors, and even transmission systems may come from specialized suppliers who focus on delivering the best quality parts.

However, these suppliers are carefully vetted to ensure that every component meets Porsche's exacting standards. This collaborative approach allows the brand to leverage cutting-edge technology while maintaining the integrity and performance Porsche is known for.

The Engine Production Process

Building a Porsche engine is no small feat. Each engine goes through a meticulous manufacturing process that blends advanced robotics with hand craftsmanship. This dual approach ensures the highest levels of precision during assembly while also allowing for the human touch that emphasizes quality control.

Porsche maintains strict quality checks at each stage of production. These checks include visual inspections, measurement tests, and functional tests to screen for any defects before the engines are shipped off to their respective vehicles. The attention to detail in the production process guarantees that every Porsche engine is built to last and provide thrilling performance for years to come.

Current Engine Line-Up

Porsche’s current engine line-up is impressive, featuring various configurations—including naturally aspirated, turbocharged, and hybrid options. Here’s a brief overview of some notable engines:

- Flat-Six Engines: Used in the infamous 911 series, known for their distinctive sound and performance traits.

- 4.0L V8 Engine: Featured in the Porsche Cayenne, delivering powerful performance and versatility.

- Electric Powertrains: As seen in the Taycan, offering stunning acceleration and innovation in electric power.

Regardless of the engine choice, each configuration embodies Porsche's dedication to performance, efficiency, and driving pleasure.

Conclusion: The Heart of Porsche

When you ask “who makes Porsche engines?” the answer is a blend of talented engineers, advanced technology, and a commitment to excellence. From in-house manufacturing to collaborations with specialized suppliers, each engine represents the culmination of over a century of automotive innovation.

As Porsche continues to evolve, one thing remains clear: the engines that power these extraordinary vehicles will always be at the forefront of engineering excellence, driving the brand's legacy forward into the future. As enthusiasts, we will undoubtedly continue to savor the delicious roar of a Porsche engine, this timeless sound of performance and precision.

With each rev of the engine, we celebrate the passionate craftsmanship, relentless innovation, and the indomitable spirit that is Porsche.